Smart logistics for a more sustainable approach

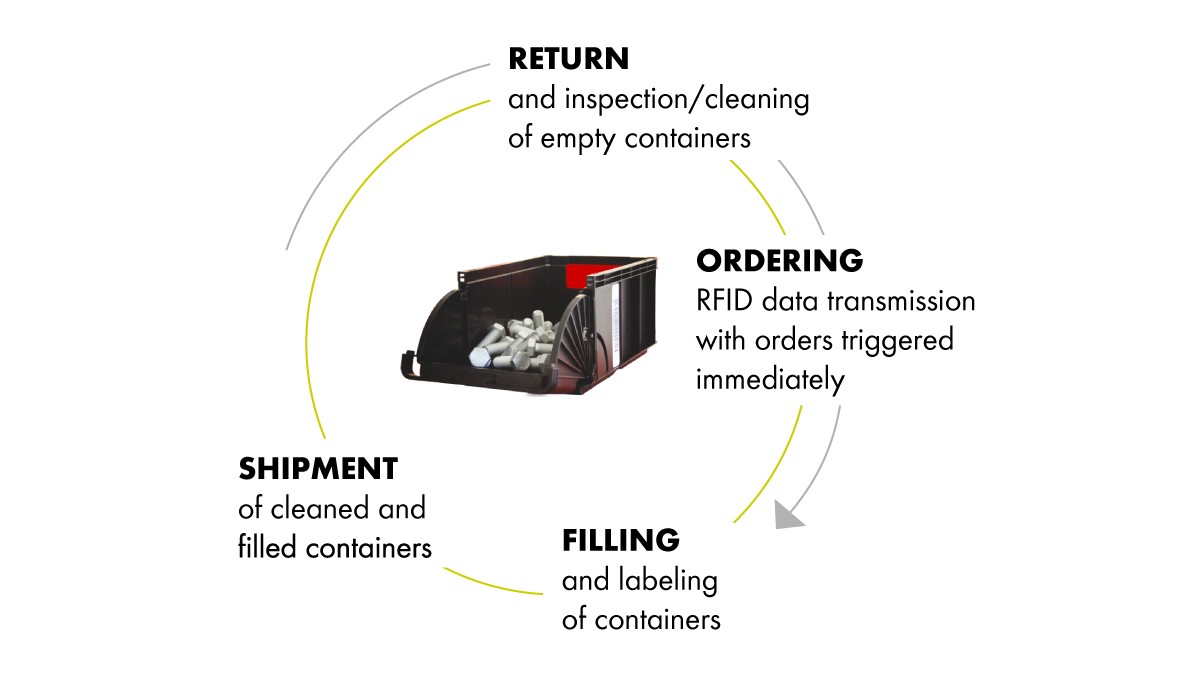

Automated system solutions that reorder products according to demand using digital and contactless technology provide for optimal supply cycles based on actual consumption, shorter reaction times, and cost-effective logistics. Highly flexible Kanban systems help manage warehousing and product activities effectively and transparently. In addition to streamlining processes, Würth Industry is also focusing on reducing its resource consumption and CO₂ emissions. Kanban bins could therefore replace traditional transport packaging and circulate multiple times through the supply and logistics cycle.

Status: The Kanban solution can help industrial manufacturing companies both avoid conventional packaging waste and reduce CO₂ emissions by up to 53% compared to a traditional manual order processing system.

Comparison of delivery types